Complete Guide: What is a Brushless Alternator | Its Construction and Positive Working Principle

What is a brushless alternator?

Brushless alternators are becoming more and more popular in the automotive world. This is because they have many advantages over traditional brushed alternators. In this article, we will discuss the construction and working principle of brushless alternators.

A brushless alternator is an electrical device that uses a rotating magnet to create energy and electricity. The magnet is mounted on a shaft that spins inside a housing, and the housing has coils of wire around it. As the magnet spins, it creates a magnetic field that induces an electric current in the field coil. The current is then sent to a load, such as a light bulb or a motor.

This article will help you understand why brushless are so popular and why you should consider using one in your next project.

The advantage of a brushless alternator over a conventional alternator

A brushless is more efficient.

In a conventional alternator, the magnet is mounted on a rotating armature with brushes that contact the field coil to create the electric current. The brushes create friction and wear out over time, which can cause the alternator to become less efficient.

A BL alternator does not have brushes, so there is no friction or wear. This makes the brushless alternator more efficient and longer lasting. In addition, a brushless alternator is usually smaller and lighter than a conventional alternator, making it easier to install and maintain.

It can convert more electrical energy power into electricity through a voltage regulator than the older alternators version (which uses carbon brushes), which means that you will use less fuel to generate the same amount of power. Finally, a brushless alternator is more durable than a brushed alternator.

The working principle of a brushless alternator

The brushless alternator is based on the electromagnetic induction principle. When a conductor, such as a copper wire, is moved through a magnetic field, an electric current is induced in the conductor. The strength of the current depends on the strength of the magnetic field, the high speed at which the conductor is moved, and the length of the conductor.

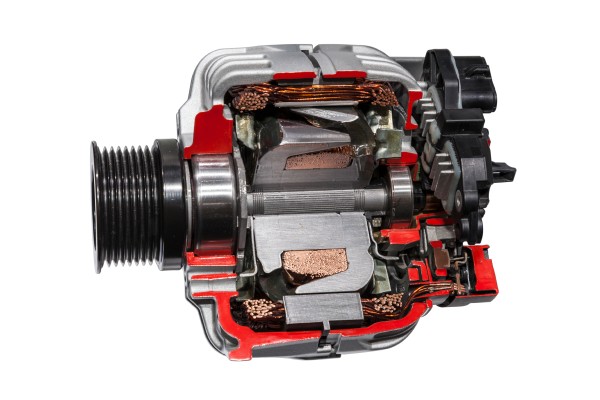

It consists of a stator, a stationary part that houses the field coil, and a rotor, which is a rotating part that contains the magnet. The stator is usually made of steel or iron, and the rotor is usually made of rare earth magnets or metals, such as neodymium or samarium.

As the rotor spins, it creates a magnetic field that induces an electric current in the field coil in the stator. The induced current flowing through the wire coils produces a magnetic field of its own, which interacts with the rotor’s magnetic field. This interaction causes the rotor to spin, which causes the stator to rotate. The rotation of the stator creates an alternating current (AC) in the coil wire.

The AC current flowing through the wire coils is then sent to a load, such as a light bulb or a motor. The load converts the AC current into DC current, which can then be used to power electrical devices.

Why it is called a brushless alternator?

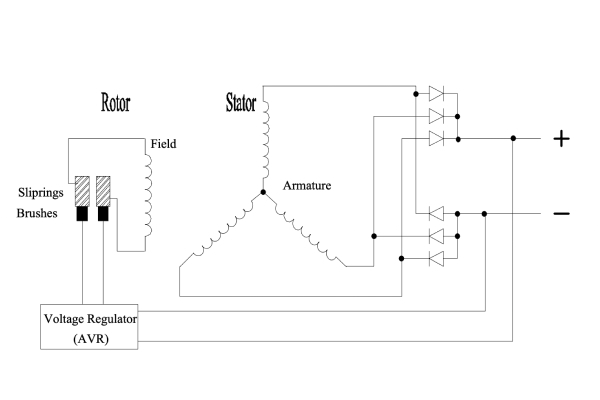

The answer lies in the fact that there are no brushes required to create the alternating electrical current. In a traditional alternator, there are rotating armature and stationary coils of wire (the stator). The armature is mounted on a shaft and spins inside the stator. Brushes are used to connect the armature to the outside world, allowing electrical current to flow in and out. In a brushless alternator, there is still a rotating armature and stationary wire coil. However, the armature is mounted on a permanent magnet one, instead of being connected to brushes. This means that the electrical current flows through the coils differently, and no brushes are required.

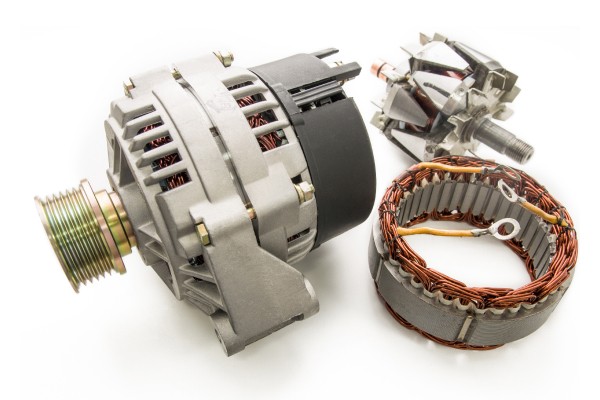

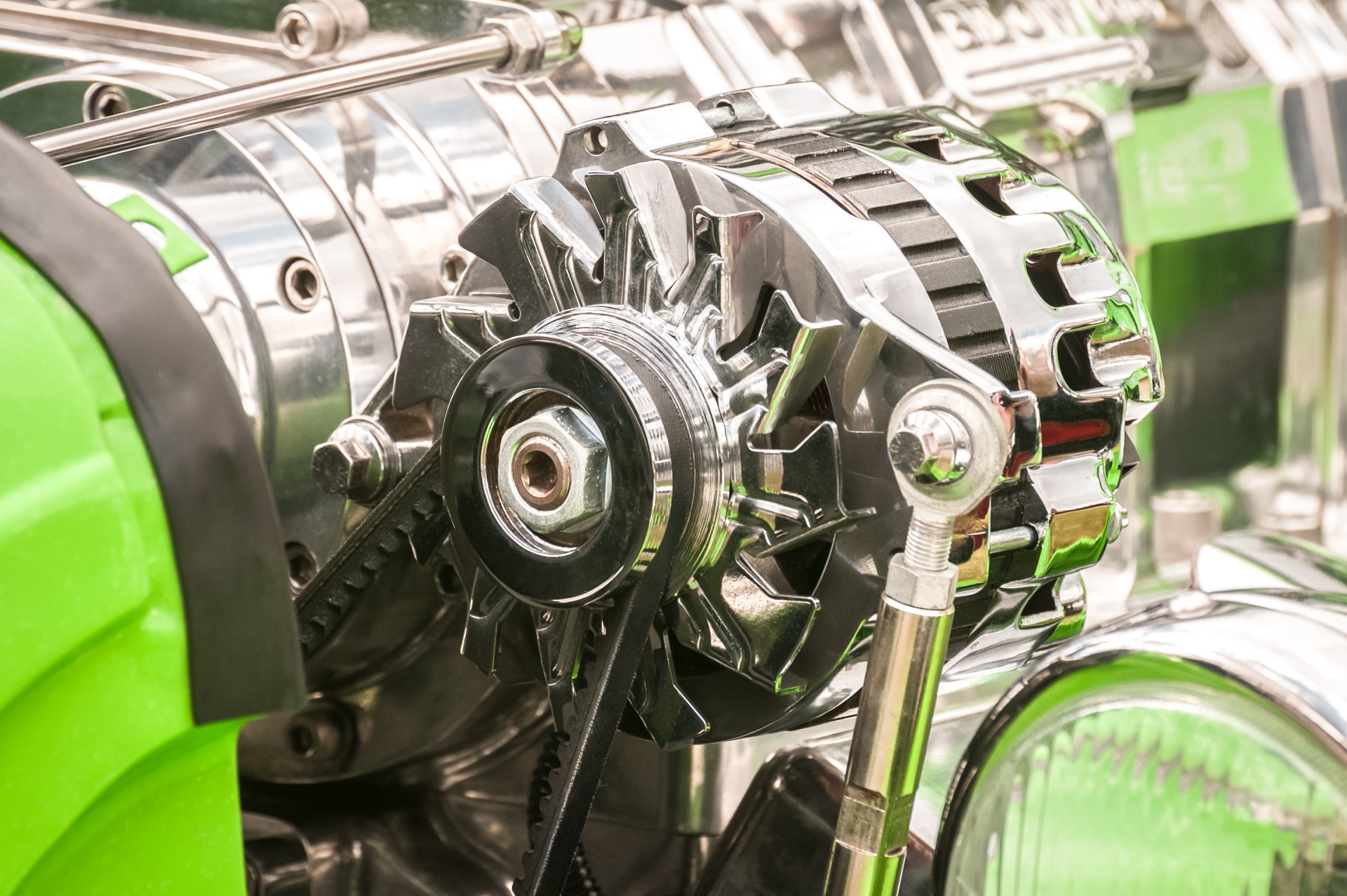

Brushless alternator construction

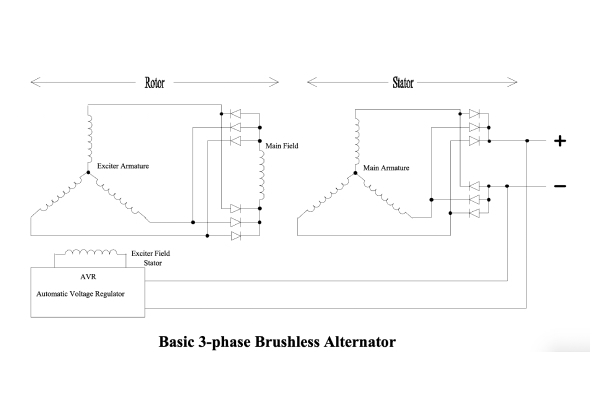

The main components of a BL generator are the stator, rotor, exciter, rectifier, and BLDC controller. The stator is the stationary part of the alternator that houses the windings. The rotor speed is the rotating part of the alternator that contains the magnets. The exciter is responsible for providing power to the field coils of the rotor. The rectifier converts the alternating electrical current from the stator windings into a direct current. The controller regulates the excitation of the field coils to control the output power voltage of the alternator.

The most common type of BL generator used in automotive applications is the 3-phase alternator. Three-phase alternators have three stator windings that are spaced 120 degrees apart. The rotor of a 3-phase alternator contains six magnets that are arranged in two pairs of north and south poles. The field coils of the rotor are excited by the DC output of the exciter.

The excitation of the field coils controls the output voltage regulator of a BL generator. The output voltage can be increased by increasing the excitation of the field coils. The output voltage can be decreased by decreasing the excitation of the field coils.

A brushless generator is also more compact than a brushed alternator. This is because the brushless generator has no carbon brushes or commutators. As a result, a brushless generator or alternator is more suited for use in automotive applications where space is limited.

A Brushless generator or alternator is also more expensive than a brushed one. This is because they are more complex and require more parts. In addition, they are less common than brushed. As a result, they are not as widely available as brushed alternators which use carbon brushes.

BL Control System

To produce a powerful magnetic field (350-400 gauss), the exciter (one of the major components) is connected to a strong current source to saturate its stationary exciter field current. This affects the quantity of output produced by the exciter. The exciter’s output is fed into the main alternator’s rotating field for generating a magnetic field. The strength of the main alternator’s magnetic field determines its mechanical heat power output. As a result, even though only a little amount of current goes through the exciter’s stationary exciter field coils, it impacts the power output of the primary alternator, and none of it has to go through brushes and slip-rings.

Parts of the BL alternator

A brushless generator or alternator is composed of a stator and a rotor. The stator is the stationary part of the alternator and consists of windings (coils) that create a magnetic field with a voltage regulator. The rotor is the rotating part of the alternator and contains magnets. As the rotor turns with the torque required, it interacts with the stator’s magnetic field to produce and conduct electricity to create energy.

The brushes in a brushless generator help transfer electricity from the rotor to the stator. The windings in the stator are connected to three rings’ slip, which are mounted on the shaft of the rotor winding and require more torque. The brushes make contact with these rings and transfer electricity to them. These conduct electricity and then flow through the stator windings and produce a magnetic field.

A brushless generator is more efficient than a brushed alternator because there are no brushes to wear out and no commutator to maintain. Additionally, brushless generator typically has lower levels of electromagnetic interference (EMI) than brushed alternators.

Are brushless better?

Yes, they are more efficient and have fewer moving parts, requiring less maintenance.

Brushless car alternator

It is an alternator that uses brushes to create an electrical connection between the spinning rotor and the stationary stator. This type of alternator is typically found in older model cars. It also is less efficient than a brushed alternator and can create more electrical noise.

How much do Alternator brushless costs?

The average cost of a BL alternator can range anywhere from $500 to upwards of $2,000. The price will depend on the brand, type, and power output. For example, a 3kW unit may cost around $500, while a more powerful 10kW unit could cost closer to $2,000. When choosing a BL alternator, it is important to consider the needs of your particular application to select the most appropriate unit. With so many options on the market, there is sure to be a BL alternator that meets your specific requirements.

You will also need to factor in the cost of installation. Installation costs will vary depending on the vehicle and the job’s complexity. Expect to pay between $200 and $500 for installation.

The cost of a BL alternator is worth the investment if you are looking for a more efficient mechanical energy and environmentally friendly way to power your vehicle. The device will save you money in the long run, and it will help reduce your carbon footprint.

Can a brushless motor be used as a generator?

Yes, a brushless motor can be used as a generator. Many motors are now brushless generators. The main advantage of using a brushless motor as a generator is that it is more efficient than a traditional brushed motor. Brushless dc motors are also more durable and require less maintenance.

How do you convert an alternator to a brushless DC motor?

There are a few key differences between an alternator and a brushless DC (BLDC) motor. First, BLDC motors have permanent magnets that rotate around the stator, while alternators have electromagnets that rotate around the rotor. Second, BLDC motors require a controller to switch the phase of the winding current, while alternators do not. Finally, BLDC motors are more efficient than alternators and can run at higher speeds as speed increases.

To convert an alternator to a BLDC motor, you will need to:

1. Remove the field winding from the rotor

2. Install permanent magnets in the place of the field winding

3. Install a controller to switch the phase of the winding current

4. Adjust the stator windings to match the new rotor configuration

5. Test the motor to ensure it is running correctly.

These simple steps can convert an alternator into a brushless DC motor. This conversion will improve the efficiency of the brushless DC motor, and allow it to run at higher speeds.

Can an alternator run an electric motor?

Yes, vehicle alternators can run an electric motor. However, the power converter an alternator can provide to an electric motor will depend on the size and type of alternator used. Additionally, the amount of power required by the electric motor will also play a role in determining how much power the alternator can provide. In general, however, most should provide enough power to run an electric motor producing electrical energy without any problems.

BL alternator vs brushed

The main difference between a BL alternator and a brushed one is that the former does not have any brushed. This means that there are no parts that need to be replaced regularly, and the overall maintenance costs are lower. In addition, brushless tends to be more efficient and generate less heat than their brushed counterparts.

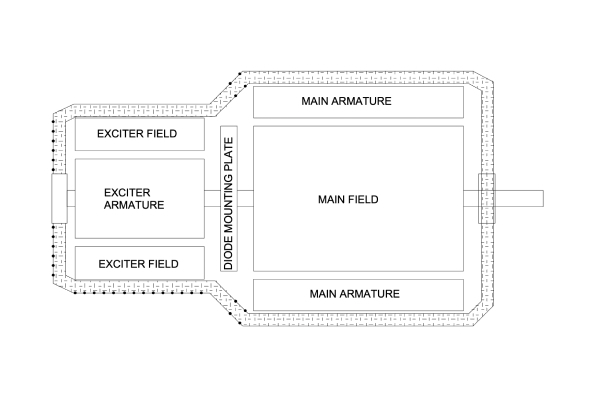

Brushless AC generator diagram

A brushless AC generator is a type of AC generator that uses no brushes. The armature and field windings are arranged in such a way that the flux paths do not intersect, eliminating the need for brushes. This type of generator is more efficient than a brushed AC generator.

The main disadvantage of a brushless AC generator is that it is more expensive than a brushed AC generator. Additionally, the commutator’s less design means that the generator must be more carefully controlled to prevent over-speeding and damage to the stator windings.

BL alternator maintenance

You can do a few things to prolong the life of your BL alternator and keep it running at peak performance.

1) Check the drive belt regularly. The drive belt is what turns the alternator’s rotor, so it’s essential that it is in good condition. Look for cracks, fraying, or other signs of wear and tear.

2) Keep the alternator clean. Dust and debris can build up on the alternator’s internal parts, causing premature wear. Use a soft cloth to gently remove any build-up.

3) Check the wiring. Over time, the alternator’s wiring can become loose or damaged. Inspect the wiring regularly for any signs of wear or damage.

4) Keep an eye on the bearings. The alternator’s bearings are what allow it to rotate smoothly. If they become worn, the alternator will have to work harder, which can shorten its lifespan.

5) Store the alternator properly. When not in use, store the alternator in a cool, dry place. This will help prevent rust and corrosion.

By following these simple tips, you can help ensure that your BL alternator will provide years of trouble-free service.

Brushless alternator 12v

A BL alternator is an electrical generator that uses brushes to convert mechanical energy (produced through potential and kinetic energy) into electricity.

How does a BL alternator work?

A BL alternator consists of a Rotor, Stator, and Rectifier. The rotor is a permanent magnet that rotates inside the stator, which is a coil of wire. The rectifier converts the alternating current (AC) generated by the rotation of the rotor into direct current (brushless DC motors).

The main advantage of a BL alternator is that it does not require brushes to convert mechanical energy into electricity. This means there is no wear and tear on the brushes, and the generator does not require periodic maintenance. Additionally, brushless generators are more efficient than brushed generators, capable of generating less electromagnetic interference (EMI).

What are the applications of a brushless alternator?

Brushless alternators are typically used in applications where reliability and efficiency are important, such as in automotive, aerospace, and military applications.

Some of the other applications of brushless alternators include:

– Wind turbines

– Electric vehicles

– Uninterrupted power supplies (UPS)

– Emergency backup generators

– Portable generators

What are the disadvantages of a brushless alternator?

The main disadvantage of a brushless AC generator is that it is more expensive than a brushed AC generator. Additionally, the commutator’s less design means that the generator must be more carefully controlled to prevent over-speeding and damage to the stator windings.

Conclusion about brushless alternators

Brushless generators or alternators are more efficient than brushed alternators, but they are also more expensive. A BL alternator is the way to go if you are looking for an efficient and affordable one.

Leave a Reply