How long does JB WELD take to dry? [Avg: 5 HRS Sets & 20 HRS Cures]

JB Weld is a multipurpose two-part epoxy adhesive developed by JELD-WEN that firmly welds metal and nonmetallic surfaces. When combined at a ratio of 1:1, it takes the form of a firm connection that can be molded, tapped, filed, sanded, and drilled after curing. This article will help you on how long does JB Weld take to dry.

Average of 5 hours to set & 20 hours to cure (JB Weld Original)

The biggest part is understanding what JB weld product you are using. After sitting at room temperature for 4-6 hours, J-B Weld Original sets, and its tensile strength reaches 5020 PSI, creating a hard bond. The full cure time is reached at 15-24 hours.

The J B Weld company offers a wide range of bonding agents. You’ll need to double check which product you are using and verify the drying time. We’ve listed out of the some products that often get used to give you the exact time need for the drying time.

J-B WELD TWIN TUBE

J-B Weld is The Original Cold Weld two-part epoxy system that give you a strong, lasting repairs to metal and multiple surfaces. Mixing at a ratio of 1:1, it will form a permanent bond and can be shaped, filed, tapped, sanded and drilled after 24 hours of curing time.

| Set Time | Cure Time | Cure Color | Strength |

| 4-6 hours | 15-24 hours | Dark grey | 5020 PSI |

KWIKWELD TWIN TUBE

KwikWeld is a fast setting version of The Original J-B Weld two-part epoxy cold weld system that provides strong, lasting repairs to metal and multiple other surface types.

| Set Time | Cure Time | Cure Color | Strength |

| 6 Minutes | 4-6 Hours | Dark grey | 3127 PSI |

MARINEWELD TWIN TUBE

MarineWeld is a specially formulated two-part epoxy cold weld system that give you a strong, lasting repair for bonding different such as aluminum, metal, fiberglass, composites, and others.

| Set Time | Cure Time | Cure Color | Strength |

| 6 Minutes | 4-6 Hours | Dark grey | 5020 PSI |

CLEARWELD TWIN TUBE

ClearWeld is made to cure with a clear and transparent bond when used at thicknesses of less than 15 mil.

| Set Time | Cure Time | Cure Color | Strength |

| 5 Minutes | 1 Hour | Clear | 3900 PSI |

How to use JB WELD?

This will guide you how to two part epoxy products by J B Weld. Preparation is essential to success in any adhesive endeavor with a permanent bond. You can guarantee that JB Weld will perform at its peak if you follow the package instructions in this article.

Preparing the surface for repair is also necessary. To get the best results, begin cleaning this surface with a detergent and degreaser. With a file or coarse sandpaper, roughen it up. It will aid in the development of a permanent bond.

J-B Weld weld stronger than welding rod. The curing time of the epoxy: resin, and hardener, is around three minutes after the resin and hardener are mixed. Using this before it dries to get the most out of your repair would be best—J-B Weld cure time to bond surfaces between 15 to 24 hours after application. Temperature and humidity factors will affect the curing time. It can cure a hard bond overnight with a tensile strength of 520 PSI.

To be clear, the J-B Weld epoxy system is not meant to be used on moving parts, nor is it meant to be used for structural repairs. Although it is for metal and multiple surfaces, non-porous materials, such as plastic and any flexible rubber surface, should be avoided.

In addition, J-B Weld’s bond strength improves with time, so wait until the repair has been fully cured before putting pressure on it. JB Weld’s manufacturer should be consulted if you are unsure if the product is appropriate for your repair.

Where to buy JB WELD?

Repairs with J-B Weld components provide lasting reliability. You may find several J-B Weld products at JBweld.com such as the J-B Weld Epoxy Compound 2oz, the JB Weld Stick Weld Epoxy Compound, JB Quik, and many others.

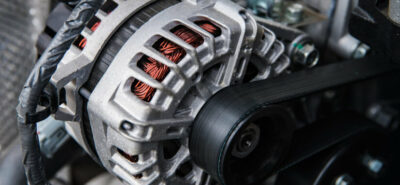

Here at Speed Alternators, we have a wide variety of original J B Weld products. Each designed for a certain purpose and suitable for use with a specific material.

How to remove J-B WELD?

Have you ever tried to weld something with JB Weld, only to realize you messed it up and need to disassemble and reweld it? A common concern is whether or not JB Weld can be removed from a welded surface.

You’ve probably witnessed firsthand the incredible strength of repairs made with JB Weld. Read on for details on removing a JB Weld and the best approach to utilize.

How to remove J-B WELD by using heat

J-B Weld can be easily stripped off metal and other heat-resistant materials by applying intense heat.

High-temperature environments destroy JB Weld. When heated above 900 degrees Fahrenheit, liquid welds like JB Weld become unstable. At a very high temperature, J B Weld will detach from the surface.

Using a heat gun or a heat lamp is a quick and simple method for eliminating cured J-B weld. The glue will come off much more easily if the material is subjected to high heat, as this will disrupt the glue’s interior chemical structure.

If you need to apply heat, a propane torch is another option. Prepare the material by heating it with a torch held at a low angle. It will melt at temperatures beyond 600 degrees.

A soldering iron is another option for working with small areas. However, waiting for the glue to heat up is impractical for larger pieces and surfaces.

Mechanical force, such as a scraper or a brush, can assist.

How to remove J-B WELD by grinding

Using a grinder to apply mechanical force is an alternative to using heat when removing J B Weld.

Angle grinders, Dremel tools, and sandpaper can all be used to remove JB Weld effectively. Wear a mask or respirator when grinding; breathing in the dust might cause serious health problems.

How to remove J-B WELD using chemicals

Some reports that using chemicals like vinegar or acetone to soften the weld made removing J B Weld easier.

If the substrate cannot tolerate high heat but is resistant to acids or acetone, the chemical removal of the J-B Weld is the best solution. One way to do it is using a lacquer thinner against its high tensile strength.

Combining processes is not recommended since using chemicals and grinding them together would produce an unmanageable mess.

Conclusion

Automobiles, home maintenance, boats, pipes, outlets, fiberglass, metals, bricks, and arts and crafts are just some of the many applications for J B Weld. In conclusion, J B Weld original cold weld is an excellent choice for repairs requiring a strong bond. It’s a great choice for many fixes because of its long-lasting bond and overnight curing.

![Can a weak alternator cause poor engine performance? [Yes & No], (speedalternators.com)](https://speedalternators.com/wp-content/uploads/2022/09/weak-alternator-e1677554040758-400x185.png)

Leave a Reply